Formwork for Specialized Concrete Shapes: Custom Solutions

We're experts at providing custom formwork solutions perfect for crafting specialized concrete shapes. We utilize materials like timber, steel or hybrid mixes, based on your project's unique demands. Modern CAD systems guarantee the precision needed for intricate column sections, tunnels or domes. The art of formwork demands not just cutting-edge technology, but also meticulous planning and even a human touch. So, whether you're after durability or flexing your creative muscles – there's always a perfect solution ready for production. Curious about the behind-the-scenes process? There's much more waiting for you into the world of concrete craftmanship.

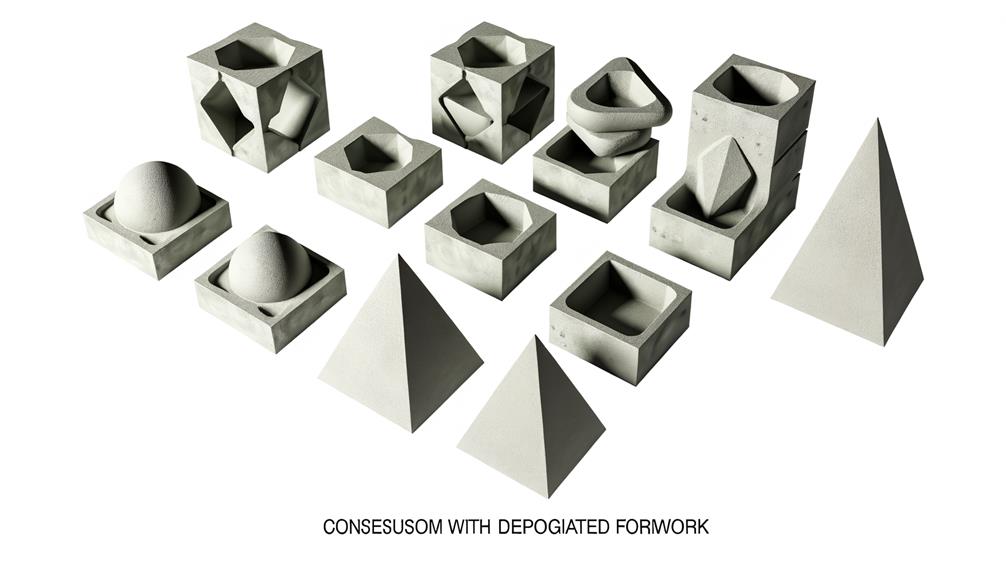

Understanding Specialized Concrete Shapes

Exploring the domain of specialized concrete shapes, we find that they require custom formwork solutions meticulously tailored to their unique geometries and surface finishes. Embracing the pursuit, companies like PASCHAL offer innovative formworks in timber, steel, or hybrid materials, ensuring the highest quality standards are met. This journey into custom formwork reveals a world of unique column sections, intricate tunnels, impressive domes, and even mushroom heads and brackets, each with its unique requirements and specifications.

Custom formwork creation is often a task for skilled steel construction or carpentry companies. The modern CAD systems they employ allow the detailed replication of the unique geometries in the formwork. This intricate design process results in a formwork that can accurately capture the desired shape and surface finish of the specialized concrete structure.

The choice between timber and steel formwork isn't arbitrary. It's a decision made based on the frequency of use, the desired surface structure, and the overall project requirements. Steel formwork, being more durable, is generally chosen for projects where the formwork will be used repeatedly. Timber, on the other hand, is preferred for its ability to deliver a specific surface finish.

In a world aiming for unique designs and architectures, specialized concrete shapes are the building blocks of innovation. Understanding the importance of accurate formwork in achieving these designs is the first step in liberating the creativity of engineers, architects, and builders. This detailed understanding of specialized concrete shapes and the formwork that shapes them is our tool for liberation in the world of construction.

The Art of Custom Formwork

Delving into the art of custom formwork, we see a symphony of precision and innovation, where every detail matters and each piece is crafted with utmost care to breathe life into specialized concrete shapes. This is a world where design meets functionality, and where creativity is set free to go hand-in-hand with construction. It's a space where solutions like PASCHAL's custom formwork come into play, providing bespoke answers to unique construction challenges.

Creating such bespoke solutions requires a delicate blend of skill, technology, and innovation. It's not just about crafting the formwork, it's about understanding the material, whether it's timber or steel, and knowing how to manipulate it to achieve the desired shape. It's about considering the project requirements, the load-bearing capacity, the pressure points, and the structural integrity.

This is an area where careful planning becomes an indispensable tool. Modern CAD systems are relied upon for design and production, ensuring accuracy and precision in every angle and curve. Yet, it's not just about the technology, but also the human touch. Specialized steel construction or carpentry companies bring their expertise, ensuring the quality and precision that's essential to the success of such complex projects.

Commissioning formwork suppliers like PASCHAL is often the chosen path for construction companies. They entrust these experts with their unique needs, knowing that their project will benefit from a custom solution that's not just functional, but also artful.

In essence, the art of custom formwork is a proof of the power of innovative thinking, precise execution, and the pursuit of construction excellence. It's about breaking boundaries, challenging norms, and bringing visions to reality, one specialized concrete shape at a time.

Advantages of Steel and Timber Formwork

Exploring the world of concrete formwork, we find that the strategic use of steel and timber offers distinct advantages for custom construction, balancing durability with cost-effectiveness and flexibility. The longevity and resilience of steel formwork make it an ideal choice for frequent use and more complex shapes. It's like a reliable warrior, capable of enduring the harsh conditions of a construction site, while delivering precision and quality in every project.

On the other hand, timber formwork shines in specialized areas where fewer uses are anticipated. It provides a cost-effective solution without compromising on the quality of the concrete structure. Timber's versatility and adaptability make it a preferred choice for those seeking economical and practical formwork solutions.

Combining these two can lead to enhanced support and flexibility for custom concrete structures. A blend of steel's durability and timber's cost-effectiveness can result in a formwork design that is both robust and economical.

To illustrate, let's consider this table:

| Material | Advantages |

|---|---|

| Steel | Long lifespan, durable, ideal for complex shapes |

| Timber | Economical, versatile, suitable for fewer uses |

| Steel + Timber | Enhanced support, flexibility, cost-effective |

Modern CAD systems are essential in designing this large-scale customized formwork, providing innovative solutions for unique concrete shapes. We rely on formwork suppliers to provide these reliable solutions, liberating us from the constraints of traditional formwork methods and opening a world of possibilities in the domain of specialized concrete formwork.

The Process of Producing Custom Formwork

When it comes to crafting custom formwork, we need to meticulously choose our materials, taking into account factors like usage frequency and the desired surface finish of the concrete structure. Timber, for instance, is ideal for limited usage due to its cost-effectiveness and ease of manipulation. However, for projects requiring high frequency usage, we tend to lean towards steel because of its exceptional durability.

The innovation doesn't stop at the selection of the material; we also strategically combine timber and steel to create hybrid solutions. By utilizing a steel frame formwork with timber infill, we achieve enhanced support for complex structures without compromising on the finished surface quality.

To tailor the formwork to the unique requirements of each project, we take into account various factors such as sizes, shapes, and heights of the structures, as well as the type of plywood to be used. The critical specifications of the project are also important in determining the method of construction.

Now, it's not just us doing all the heavy lifting. We often collaborate with construction companies, working in synergy to deliver the best results. By engaging formwork suppliers, we're able to create custom formwork that caters to specialized concrete shapes. This not only allows for an efficient construction process, but also guarantees a superior finished product.

Custom Solutions: Our Commitment

In our dedication to providing custom solutions, we at PASCHAL consistently deliver tailor-made formwork that caters to a wide array of specialized concrete shapes, including complex structures like shaft formwork, special column sections, tunnels, domes, mushroom heads, and brackets. We craft these custom solutions from timber, steel, or a combination of materials to meet the highest quality standards and project-specific necessities.

The process of creating custom formwork demands careful planning and meticulous execution. We don't shy away from this challenge; indeed, we embrace it, using modern CAD systems to guarantee precision. And, when the project scale warrants it, we conduct trial set-ups to verify accuracy before the final installation.

We understand that construction companies often rely on us to provide formwork solutions for unique and complex concrete structures. We take this responsibility seriously, guiding our clients in selecting the most suitable materials based on factors such as size, shape, height, plywood requirements, and technical specifications.

Timber, for instance, is a versatile option for limited use cases, offering affordability and flexibility. Steel, on the other hand, is perfect for durability and frequent applications, demonstrating resilience even in the face of stringent demands.

Visual and Architectural Concrete Finishes

Exploring the realm of visual and architectural concrete finishes, we find that achieving an exceptional aesthetic appeal requires meticulous attention to surface finish requirements. To create concrete forms with stunning visual impact, we must consider surface regularity, color consistency, and overall quality. It's not just about pouring and setting; it's about a calculated synergy of materials, formwork, and compaction techniques.

Collaboration is the key. We've discovered that by working closely with all stakeholders, we can guarantee the desired finish is realized. This includes specific requirements for surface regularity, color variation, blowholes, structure edges, and formwork joint arrangements. Every detail is important and contributes to the final visual and architectural impact.

Central to our process is the selection of materials. The right formwork can shape and mold the concrete, while the careful choice of compaction techniques ensures a uniform and smooth surface. It's a delicate balance of art and science that we've honed over time.

Consideration also extends to factors like water/cement ratio and concrete temperature evolution. These seemingly small details can significantly impact the surface finish quality. That's why we also conduct trial panels assessment, allowing us to perfect our process before the main pour.

Exploring Structural Concrete Formwork

Shifting our focus to structural concrete formwork, we explore the intricacies of developing specialized concrete shapes, a process made possible through companies like PASCHAL and their custom formwork solutions. These solutions help create unique structures, from shaft formwork, special column sections, tunnels, to domes, mushroom heads, and brackets, each requiring a different formwork type.

Custom formwork, a blend of timber, steel, or a combination of these materials, caters to specific project requirements. Let's compare the two primary types: steel and timber, in the table below:

| Material | Advantages |

|---|---|

| Steel | Durable, long service life, high usage |

| Timber | Economical, flexible, easy to manipulate |

Steel formwork, though slightly expensive, offers longevity and durability, especially for high usage. On the other hand, timber formwork is economical and offers flexibility, aiding in creating unique shapes.

When it comes to large-scale custom formwork, it's a game of precision and thorough planning. Modern CAD systems come into play, enabling accurate design and detailing. Sometimes, trial set-ups are executed to guarantee the desired quality and accuracy.

We can't ignore the role of formwork suppliers in this process. Construction companies often commission suppliers like PASCHAL to design specialized formwork to meet unique project needs. It's a collaborative effort where the supplier's expertise meets the construction company's vision, resulting in a concrete structure that is not only functional but also a piece of architectural art. In this scenario, specialized concrete formwork isn't just a means to an end; it's an innovative tool for architectural expression.

Precision in Flatwork for Concrete

As we explore further into the world of concrete construction, accuracy in flatwork for concrete commands our attention, a meticulous process that guarantees smooth and level finishes for horizontal surfaces like floors and driveways. Precision flatwork is paramount in creating durable structures that meet long-term functionality requirements. This involves a detailed approach to achieve both structural integrity and visual appeal in concrete projects.

Let's delve into why precision in flatwork is vital:

- Structural Integrity: Skilled execution of flatwork ensures the structural soundness of the concrete structure. This means the structure can withstand external pressures without compromising its stability.

- Aesthetic Appeal: Professional precision in flatwork results not only in level surfaces but also in surfaces that are visually pleasing. A smooth, even finish enhances the overall look of the concrete structure, adding value to the property.

- Long-term Functionality: Properly executed flatwork can significantly extend the lifespan of a structure, reducing the need for frequent repairs or replacements. This is a cost-effective solution in the long run.

- Turnkey Operations: These handle all aspects of flatwork seamlessly, guaranteeing a high-quality and lasting finish. They ensure precision at every step, from the initial pouring to the final finishing.

Precision in flatwork is more than just creating flat surfaces. It's a meticulous process that integrates structural integrity, aesthetics, and long-term functionality into a seamless whole. As we continue to push the boundaries of concrete construction, precision in flatwork remains a cornerstone in our pursuit of excellence. The freedom to create durable, beautiful, and efficient structures is within our grasp. And that, indeed, is liberating.

Safety Measures in Formwork

While precision in flatwork provides a solid foundation for concrete construction, focusing on safety measures in formwork is equally vital to prevent accidents, assure compliance with regulations, and maintain a safe working environment for construction crews. It's not just about getting the job done; it's about doing it safely and efficiently.

Training our workers is our first line of defense. We make sure that they're well-versed in OSHA regulations and adept in the use of all equipment and tools. This isn't just about ticking a compliance box; it's about empowering our crew with the knowledge and skills they need to work safely and confidently.

We're also big on proactive safety measures. We install fall protection systems, guardrails, and safety nets on our formwork structures. These aren't mere afterthoughts; they're integral parts of our construction process, designed to safeguard our workers from potential harm. Regular inspections of formwork components and connections are part and parcel of our safety protocol, helping us identify and rectify potential hazards promptly.

Creating a conducive working environment is another essential aspect of our safety measures. We provide adequate lighting and ventilation in our formwork areas, taking care not to compromise on worker comfort and safety. We recognize that a well-lit, well-ventilated workspace not only fosters productivity but also reduces the risk of accidents.

Achieving Aesthetic Excellence

Beyond guaranteeing safety and precision, we're dedicated to achieving aesthetic excellence in our concrete constructions, utilizing custom formwork to create specialized shapes that meet design requirements and surpass visual expectations. More than just a structural necessity, formwork has become an artistic tool in the hands of skilled professionals, allowing for the creation of unique and intricate concrete structures.

This aesthetic excellence is no coincidence but the outcome of an innovative and detailed approach to formwork design. Custom formwork enables us to mold concrete with exceptional precision, shaping it to the exact specifications of the design. This process inevitably leads to superior visual outcomes, as the final concrete shapes meet not only functional needs but also desired architectural standards.

To emphasize the role of custom formwork in achieving aesthetic excellence, consider these four key points:

- Custom formwork allows for the creation of specialized shapes, going beyond simple box-like constructions to include intricate forms that cater to the most daring and creative design visions.

- Tailored to meet specific design requirements, custom formwork enables a level of precision and control that's simply unattainable with off-the-shelf solutions.

- Far from being a mere structural necessity, well-designed formwork is an artistic tool that can bring an architect's vision to life in concrete form.

- By taking into account detailed surface finish requirements, custom formwork ensures that the final product doesn't just function well but also looks stunning.

In our quest for aesthetic excellence, we've found custom formwork to be an indispensable ally, providing the freedom to explore and create without constraints.

Problem-Solving in Formwork Design

Exploring the intricacies of formwork design, we employ advanced engineering techniques and modern CAD systems to develop tailored solutions that meet specific project requirements and guarantee accurate shaping and support for specialized concrete structures. Our focus is on problem-solving, making sure that each design meets the unique geometrical and surface needs of every project, delivering high-quality results every time.

We're not just about creating a mold; we're about offering solutions that shape the future of construction. We grasp the complexities involved in designing formwork for specialized shapes like shafts, special column sections, tunnels, domes, mushroom heads, and brackets. It's not just about getting the job done, but about doing it with precision and excellence.

To highlight our process, consider the table below:

| Step in Design Process | Technique Used | Outcome |

|---|---|---|

| Understanding project requirements | Advanced Engineering Techniques | Tailored Solutions |

| Creating the design | Modern CAD Systems | Accurate Shaping |

| Review and implementation | Problem-solving approach | High-Quality Results |

This table shows how we transform project requirements into concrete realities. We begin by comprehending the project's specific needs, then create the design using cutting-edge technology. Lastly, through a rigorous review and implementation process, we confirm that our formwork design meets and exceeds expectations.

The Unique Advantages of Form Up Foundations

Delivering personalized formwork solutions for specialized concrete shapes, we at Form Up Foundations assure that exact project requirements are fulfilled, distinguishing ourselves with our unique advantages. Our dedication to excellence, reliability, and a complete approach to every project guarantees a stress-free construction experience for our clients.

Our unique advantages include:

- *Customized Solutions*: We acknowledge that each project is distinct and necessitates a specific approach. That's why we provide tailored formwork solutions, crafted to meet the precise requirements of each client's project.

- *Productivity and Quality*: Our complete approach means we manage all facets of the concrete work, from design to implementation. This leads to a streamlined process, saving time and ensuring a top-notch result.

- *Coordinated Integration*: We ensure smooth progressions between all project phases. Our integrated coordination throughout all stages guarantees a successful result and a seamless construction experience.

- *Safety Procedures*: Upholding the highest safety standards is a priority for us. We're OSHA certified and have strict safety protocols in place to prevent hazards and uphold the integrity of our work.

Essentially, we're not just constructing structures, we're building trust and enduring relationships with our clients. Our innovative approach coupled with our attention to detail ensures that we deliver on our commitments, offering a freeing construction experience where clients can have confidence in the quality of the result. With Form Up Foundations, you're not just hiring a contractor, you're teaming up with a group dedicated to surpassing your expectations.

Frequently Asked Questions

What Is Formwork for Special Structure?

We're discussing special structure formwork. This is a custom solution used in construction to create unique concrete shapes.

We can tailor these to fit specific needs using materials like timber and steel. Careful planning and modern CAD systems are crucial for large-scale projects. It's often outsourced to guarantee precision.

This gives us the freedom to create innovative, high-quality structures without being restricted by conventional formwork limitations.

What Are the Different Types of Formwork Used in Different Types of Concrete Construction?

We're using different types of formwork in various concrete construction projects. These include timber, steel, or a combination of both. Tailored to any geometry, they meet high quality standards.

Examples of specialized formwork are shaft formwork, special column sections, tunnels, domes, and more. Large-scale projects require careful planning and modern CAD systems.

It's a complex but necessary part of construction.

What Is BS EN 13670?

We're discussing BS EN 13670, an essential European standard. It's replaced the old BS 8110 for concrete finishes, ensuring stringent guidelines for in-situ concrete work.

This covers various aspects like surface regularity, color, blowholes, and tolerances. It's all about quality and performance in concrete structures.

To achieve high-quality, enduring concrete finishes in construction, compliance with BS EN 13670 is absolutely necessary. It's a game-changer for the industry.

What Is F4 Concrete Finish Uk?

We're discussing the F4 concrete finish in the UK, a high-quality, visually appealing surface. It's a specialized finish, requiring consistent color and precise formwork.

To achieve this, we adhere to strict standards in design, material selection, and construction practices. It's often specified for architectural or decorative uses, showcasing our commitment to craftsmanship and innovation.

We're all about liberating design potentials with such detailed finishes.

Conclusion

At Form Up Foundations, we're passionate about creating custom formwork for specialized concrete shapes. Our commitment to safety, aesthetic excellence, and innovative problem-solving enables us to produce efficient steel and timber solutions.

We believe in the art of formwork and its transformative power in design. With us, you'll achieve exceptional results tailored to your unique needs.

Let's revolutionize the construction industry together with our custom formwork solutions.