Formwork for High-Rise Buildings: Design Considerations and Innovations

In high-rise construction, we're reinventing formwork design. It's all about choosing the right materials, be it timber, steel, or aluminum, factoring in safety, labor, and site dynamics. We're harnessing innovative technologies to improve efficiency and champion sustainability. Advancements like sliding formwork increase safety, while digital modeling tools simplify complex designs. We're also achieving cost-effectiveness through reusable systems and reducing waste. But it doesn't end there, delving deeper into this domain opens up a world where innovative solutions meet architectural challenges head-on. Exploring further might just revolutionize your understanding of high-rise construction formwork.

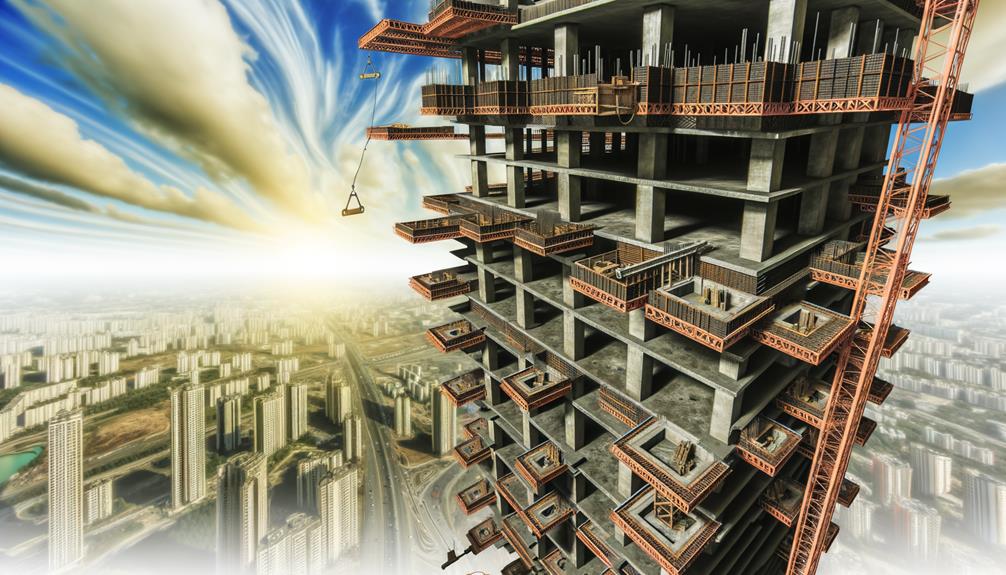

Understanding High-Rise Building Formwork

To fully grasp the significance of high-rise building formwork, we must first understand that it's pivotal in shaping concrete elements in towering structures, optimizing construction sequences and resource allocation in such expansive projects. Formwork systems, by their very nature, create the architectural shell of our modern skylines, translating design vision into tangible reality. Without them, the audacious forms of contemporary architecture would remain mere fantasy.

The beauty of formwork technology lies in its adaptability. We're not confined to a one-size-fits-all approach. We can choose from timber, steel, or aluminum, each material presenting unique benefits and challenges. Timber, for instance, offers versatility and cost-effectiveness. Steel, though pricier, provides superior strength and durability, while aluminum strikes a balance between weight and resilience.

However, material selection isn't an arbitrary decision. It's influenced by multiple factors like design complexity, labor availability, and site dynamics. Think of it as a strategic puzzle – we must align the pieces to craft an efficient and effective construction process.

As we move forward, we witness an exciting surge in innovative formwork technologies. These innovations aren't just improving efficiency and safety – they're revolutionizing the very way we construct high-rise buildings. We can now achieve more complex designs, reduce construction times, and minimize waste, bringing us closer to a sustainable construction future.

Safety Considerations in Formwork Design

As we explore the domain of safety considerations in formwork design, we find that modern advancements aren't merely focused on efficiency but are heavily invested in incorporating safety elements, fundamentally transforming the way we protect our construction workers at various heights. Safety isn't a secondary concern, it's a prevailing principle driving the evolution of formwork designs.

- Sliding Formwork: This mechanism guarantees a consistent pouring rate, enhancing safety in high-rise building construction. It's a step forward in eliminating the risks of uncontrolled pouring that could lead to structural instability and accidents.

- Climbing Formwork Devices: These innovative devices improve safety and productivity for workers at great heights during construction. They're a proof to the idea that safety and productivity can, and should, coexist in the construction industry.

- Safety Measures in Formwork Techniques: These are non-negotiable in our pursuit of a secure construction environment. Risk mitigation is more than just a buzzword; it's a mandate that we're committed to fulfilling.

We aren't merely observing these safety considerations, but actively integrating them into our designs, setting a new safety paradigm in the construction industry. We're not just building structures; we're building trust, confidence, and assurance among our workers that their well-being is paramount.

Safety in formwork design isn't merely an innovation; it's a revolution, a transformation of the construction landscape. It's not just about making work safer; it's about making work human, about acknowledging and addressing the inherent risks in constructing high-rise buildings. In doing so, we're not just shaping skylines, but also shaping a safer future for our workers.

Efficiency in High-Rise Construction Formwork

Delving into the domain of efficiency in high-rise construction formwork, we discern that its impact is far-reaching, revolutionizing not just concrete activities and resource allocation, but also shaping the overall construction sequence for a safer, waste-reduced workspace. With a keen eye on conservation and sustainability, we grasp the power of efficient formwork systems in fostering a culture of resourcefulness and economic prudence.

In our journey towards best construction practices, we've observed the advantages of repetitive construction tasks – these contribute to a seamless workflow, reduce idle times, and exploit the power of learning curve effects. We've learned to appreciate the rhythm of repeated tasks, recognizing it as the heartbeat of an efficient construction site pulsating with productivity.

As we navigate through the complex labyrinth of high-rise construction, spatial constraints in vertical and horizontal directions present unique challenges. Yet, they also inspire innovative formwork selection and scheduling solutions. We've learned to see these constraints not as obstacles, but as catalysts for creativity and ingenious problem-solving.

In our pursuit of efficiency, we've embraced the transformative power of technology. Innovations in formwork systems have ushered in a new era of enhanced efficiency, safety, and process optimization in high-rise construction. We've witnessed the metamorphosis of construction sites into technologically-advanced workspaces, a proof of our collective quest for progress.

Efficiency in high-rise construction formwork isn't just about doing more with less – it's about imagining, innovating, and implementing strategies that liberate us from wasteful practices, ushering in a new era of sustainable and responsible construction.

Cost-Effective Formwork Solutions

While we've celebrated the role of efficiency in high-rise construction formwork, it's equally important to recognize the impact of cost-effective formwork solutions. These solutions, when deployed smartly, can greatly reduce construction expenses. By optimizing material usage and labor efficiency, we can achieve a leaner, more cost-effective construction process.

Innovative formwork designs play an important role in this cost reduction. By minimizing waste and rework, we can achieve substantial savings in high-rise construction projects. These innovative designs aren't just about being aesthetically pleasing, but also about enhancing productivity and workflow continuity.

Let's consider three key ways in which cost-effective formwork solutions can be implemented:

- Utilizing Reusable Formwork Systems: By reusing formwork systems, we can lower overall project expenses. The reduction in the need for frequent replacements is a significant cost advantage.

- Proper Planning and Selection of Formwork Materials: This isn't about compromising on quality but about choosing the right materials that offer durability and performance at a lower cost.

- Implementing Efficient Formwork Solutions: Efficient solutions aren't just about speed but also about reducing costs over the entire construction process.

In this era of financial prudence, it's paramount that we liberate ourselves from traditional construction methods that are cost-intensive. Embracing cost-effective formwork solutions is a vital step towards creating high-rise buildings that aren't just structurally sound, but also financially viable. The future of construction lies in the perfect balance between efficiency and cost-effectiveness.

Innovations in Formwork Materials

The landscape of formwork materials is transforming, with innovative materials like aluminum, steel, timber, and advanced composites revolutionizing the high-rise construction industry. We're witnessing a shift toward materials that not only meet project requirements but also reflect our commitment to sustainability and efficiency.

Aluminum formwork, with its lightweight nature and reusability, is gaining popularity. It's an investment in speed and labor cost reduction. This material is transforming the industry, bringing us closer to our vision of streamlined, efficient construction processes.

In the domain of durability and strength, steel formwork reigns supreme. Suitable for heavy-duty applications, it's our go-to choice for large-scale high-rise projects. Steel embodies our dedication to robust, enduring structures that stand the test of time.

Yet, we can't overlook the importance of timber formwork. Its cost-effectiveness and ease of handling make it an ideal choice for smaller-scale projects. Timber reminds us that innovation isn't just about the new and shiny, but also about optimizing traditional methods.

Finally, we're pushing boundaries with advanced composites like fiberglass-reinforced plastic (FRP). These materials offer corrosion resistance and a high strength-to-weight ratio. They represent our dedication to exploring uncharted territories, seeking materials that offer unique benefits.

Our selection of formwork materials isn't just about project requirements or budget constraints. It's about liberation from the old ways, embracing innovation, and working towards efficient construction efficiency. Together, we're building a future that's not just taller but also smarter and more sustainable.

Digital Modeling and Formwork Design

In our pursuit for smarter, more efficient construction, we're harnessing the power of digital modeling to revolutionize formwork design for high-rise buildings. Riding the wave of digital transformation, we're leveraging 3D modeling software, virtual simulations, and computer-aided design (CAD) programs to bring about a paradigm shift in the way we approach formwork design.

- 3D Modeling Software: This digital tool has become an indispensable part of our design arsenal, enabling precise visualization of formwork designs. With the power to create accurate models, we're able to plan and adjust formwork systems to the minutest detail, thereby minimizing wastage and maximizing efficiency.

- Virtual Simulations: These are our crystal balls, foreseeing potential issues and optimizing formwork layouts before a single piece of formwork is set in place. We're no longer confined to dealing with challenges in real-time; we're proactively addressing them in the digital domain.

- CAD Programs: These are our architects' sketchpads, streamlining the design process for complex high-rise structures. By bringing designers, engineers, and construction teams onto a unified platform, we're enhancing collaboration and bringing our collective expertise to bear on each project.

Digital modeling in formwork design isn't just an incremental improvement; it's a quantum leap forward. It's a fusion of technology and creativity, of precision and flexibility. It's our key to liberating the full potential of formwork, to shaping the skylines of tomorrow with the digital tools of today. Digital modeling isn't the future of formwork design; it's the present. Let's embrace it. Let's liberate formwork from the constraints of traditional methods and let innovation take flight.

Sustainable Formwork Practices for Urban Development

As we revolutionize formwork design with digital modeling, we're also prioritizing sustainability, focusing on how we can lessen our environmental impact while constructing high-rise buildings. The key here is the adoption of sustainable formwork practices, an essential feature in progressive urban development.

We're envisioning a future where formwork no longer contributes to waste generation. How? By implementing reusable formwork systems. These innovative systems minimize resource consumption, aligning construction with the principles of sustainability, and liberating us from a cycle of wastefulness.

But, it's not just about reducing waste. We're also focusing on the materials we use. By utilizing recycled materials for formwork construction, we're not just repurposing waste; we're transforming it into a resource, a pivotal step towards a circular economy.

In our pursuit of sustainability, we're also harnessing green formwork technologies. These technologies make sure that the construction of high-rise buildings becomes an eco-friendly process. They help us build not just for the present, but for a future where urban landscapes and environmental responsibility harmoniously coexist.

Sustainable formwork practices don't just align with urban development strategies; they're integral to them. They're the blueprint for a greener future, a future where high-rise buildings don't just touch the sky, but also respect the earth. As we innovate in formwork design, we're not just building taller; we're building smarter. We're not just constructing a skyline; we're shaping a sustainable legacy. This is our vision, and we're making it a reality, one building at a time.

Frequently Asked Questions

Which Formwork Is Suitable for High-Rise Building?

We're often asked which formwork is suitable for high-rise buildings. It really depends on the specifics of your project. Climbing formwork systems are common, but self-climbing and hydraulic climbing formwork offer efficient and safe solutions.

Jumpform systems are practical for buildings with repetitive layouts. If your design includes straight vertical elements, slipform construction could be ideal. It's all about finding the right fit for your build.

What Is the Importance of New Formwork System in Highrise Building?

We're acknowledging the vital role new formwork systems play in high-rise construction. They streamline procedures, ensuring precision and efficiency. They're transforming the way we allocate resources, reducing waste, and enhancing productivity. They're also prioritizing worker safety at dizzying heights.

Embracing these innovative systems, we're seeing faster construction times with improved quality control. It's evident; these advancements are revolutionizing high-rise construction.

What Are the Design Considerations of Tall Buildings?

We're always considering key design elements in tall buildings.

We examine core layout optimization, as it's crucial for cost savings and faster construction. We also adjust the core wall's thickness based on the building's height, ensuring structural integrity.

Additionally, we carefully place the core to enhance stability and torsion resistance. And we never overlook the importance of coordinating between core walls, columns, and flooring systems.

It's a complex process, but it's what we excel at.

What Are the Construction Techniques for High-Rise Building?

We're constantly exploring innovative construction techniques for high-rise buildings. We often use slipform and jumpform methods for building cores. We favor concrete due to its fire-resistant properties and durability when pumped to high levels.

The core design plays an important role in bearing loads. But, it's the collaboration among our team that truly brings about best solutions.

We're committed to pushing boundaries and delivering visionary results in high-rise construction.

Conclusion

In closing, we've dissected the intricate aspects of formwork for high-rise buildings, highlighting the necessity of safety, efficiency, and cost-effectiveness.

New materials and digital modeling are revolutionizing the field, paving the way for more sustainable urban development.

As we move forward, it's clear we're not just building skyscrapers; we're shaping the skyline of the future with every innovative, well-calculated decision we make.

Let's continue to push boundaries and redefine the limits of formwork design.