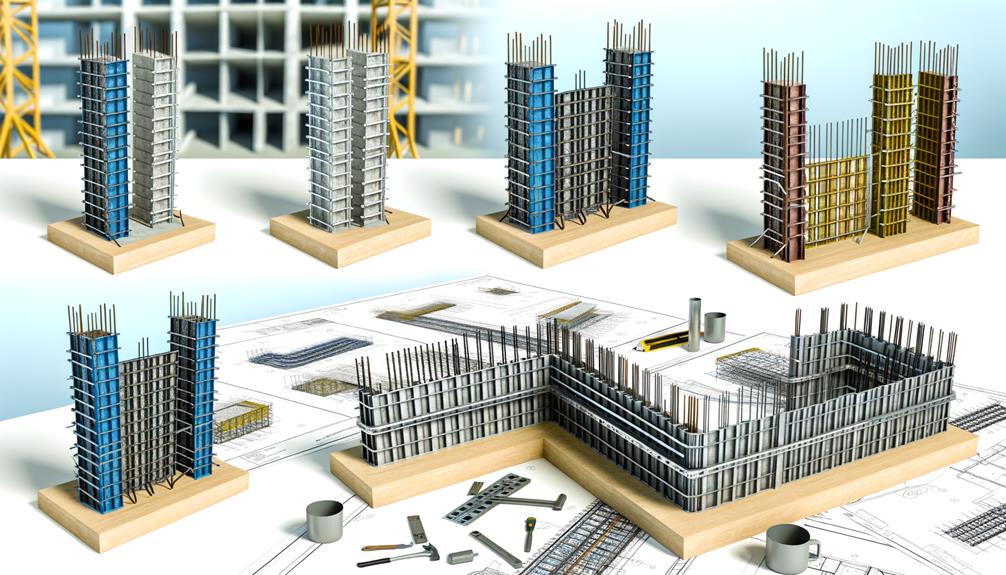

Formwork for Column Construction: Types and Methods

Formwork for column construction is a temp mold determining size, shape, and alignment. Factors like column dimension, load-bearing capacity, and material type impact design. Steel, aluminum, plastic, and plywood are common; each offering its own pros and cons. We also focus on creating effective systems, such as circular and foldable formworks, ensuring efficiency, safety, and cost-effectiveness. Additional steps like proper shutter placement, tie bolts use, and meticulous bracing ensure peak results. We also touch on safety measures and formwork removal process. Intrigued? There's a wealth of additional insights waiting to be uncovered.

Understanding Formwork Basics

To fully grasp the essence of column construction, it's imperative that we first understand the basics of formwork, a temporary mold used for shaping concrete columns to guarantee their correct size, shape, and alignment during the construction process. Formwork serves as a critical tool in construction, acting as a guide for the concrete, ensuring it solidifies in the exact dimensions required. It's not just about creating a structure; it's about crafting a robust and reliable one.

The strength and rigidity of formwork are crucial. It must withstand the pressure of wet concrete without buckling or shifting. The importance of this strength can't be overstated. If the formwork fails, the entire column's integrity is at risk. We're not just talking about aesthetics here. We're discussing the very backbone of our structures, the pillars that hold up our buildings and bridges.

There's a certain art to formwork. Different types are used for various shapes: circular, rectangular, or custom. Each type requires careful planning and implementation. The formwork's installation can make or break the final outcome. If it's not installed correctly, the consequences can be severe. It's not just the column that could be off; the entire building's alignment could be compromised.

In the end, understanding formwork is about more than just knowing how to build a column. It's about understanding the importance of precision, the value of strength, and the art of construction. It's about liberating ourselves from the constraints of the ordinary and stepping into the extraordinary world of structural engineering. It's about building not just structures, but the future.

Designing Effective Formwork Systems

When it comes to designing effective formwork systems, we must consider factors such as column size, shape, height, and load-bearing capacity to guarantee the structural integrity of the finished column. We can't forget that these systems are tasked with supporting the weight of concrete and reinforcement materials during the pouring and curing stages. It's not just about creating a mold; it's about providing robust support to assure the stability of the structure being built.

We also need to think about the ease of formwork removal, the quality of the concrete finish, and, most importantly, safety during the construction process. We're dealing with heavy materials and significant heights, so the formwork system needs to be secure, sturdy, and reliable. We can't afford any mishaps.

However, we mustn't let these considerations limit us. We should also aim to improve construction efficiency, reduce labor costs, and enhance overall project timelines. Advanced formwork systems allow us to do just that. They may require a greater initial investment, but the potential savings in time and labor often justify the expense.

Diverse Formwork Materials

Delving into the world of various formwork materials, we discover that the choice between steel, aluminium, plastic, or plywood can greatly impact the efficiency, cost, and overall quality of the column construction. Each material comes with its unique strengths and limitations, making them more suitable for particular types of structures.

Steel, for instance, is an excellent choice for circular or curved column structures. Its strength and durability provide outstanding concrete surfaces. However, the cost of steel may be prohibitive for some projects.

Aluminium, on the other hand, offers a cost-effective solution for symmetrical column designs. It also speeds up the construction process, saving valuable time and resources.

For small projects with lower fresh concrete pressure, plastic formwork provides a lightweight and crane-independent option. Its ease of handling is a significant advantage, particularly for projects with constrained resources.

Plywood is a less expensive alternative to steel, but its susceptibility to moisture absorption reduces its durability. It's a trade-off that requires careful consideration.

Finally, it's worth noting that plastic formwork systems require more parts for stability compared to steel or aluminium systems. This additional requirement can complicate assembly and increase costs.

In summary, the choice of formwork materials should be:

- Guided by the nature and scale of the project.

- Influenced by the available resources and budget.

- Determined by the desired quality of the finished structure.

- Informed by the potential for reusability and longevity.

- Considered in light of the ease and speed of assembly.

Erecting Column Formwork

When we explore the process of setting up column formwork, it's important to acknowledge that we utilize column clamps and steel wedges for assembly, aiding in stability and safety throughout the construction process. These clamps are strategically placed in alternating positions to prevent the column from twisting during construction, a forward-thinking strategy that prioritizes the structural integrity of the build.

The role of Acrow props in this process can't be overstated. Commonly utilized in the industry, these props provide essential support for the formwork. We make sure these props are appropriately positioned to carry the load of the column formwork effectively.

Another key aspect of column formwork erection is the placement of formwork shutters. These shutters, when correctly positioned, contribute significantly to the structural integrity and shape of the column. This attention to detail in shutter placement is an analytical approach we adopt to maintain the quality of construction, ensuring that the resulting structure is robust and fit for purpose.

For larger columns, we employ the use of tie bolts. These are instrumental in bolstering the stability and safety of the formwork, particularly in larger builds. The use of tie bolts is a perfect example of how we anticipate potential challenges and proactively address them.

Through these methods, we liberate the construction process from unnecessary risks, making sure that the erection of column formwork is as safe and efficient as possible. This approach demonstrates our commitment to pushing the boundaries of conventional practice, for a more liberated and advanced construction process.

Specialized Formwork Systems

Turning our attention to specialized formwork systems, we find that these include steel formwork for circular columns and foldable formwork ideal for great heights. These types of formwork bear the mark of technological progression in construction, offering solutions tailored to specific design requirements. They symbolize the industry's move towards efficiency, safety, and innovation; they're a confirmation of our collective desire for liberation from outdated techniques.

These specialized formwork systems ensure closed load transmission, a critical aspect in maintaining structural integrity during the column construction. They provide remarkable benefits, which we'll outline:

- Durable and Strong: Circular column formwork is typically made from steel. This robust material guarantees longevity and resilience, ensuring a reliable performance throughout the construction process.

- Efficient and Safe: Foldable formwork is ideal for constructing columns at significant heights. It enables workers to perform their tasks efficiently without compromising safety.

- Single-use Options: For certain projects, single-use forms are available. They offer a cost-effective solution when the reuse of formwork isn't necessary or feasible.

- Customizable: These systems can be tailored to fit specific design requirements. This flexibility allows for creativity and innovation in architectural design.

- Ensures Load Transmission: The formwork systems provide closed load transmission. This feature is essential in preventing structural failures and ensuring the stability of the column.

In our quest for liberation in construction, these systems are our allies. As we continue to explore and innovate, we're certain that the future holds even more promising formwork solutions.

Safety Measures in Formwork

Delving into the domain of formwork construction, we must prioritize safety measures to guarantee structural stability and prevent any potential accidents. We've recognized that bracing elements in formwork need to be meticulously designed by competent individuals. It's not just about erecting the formwork; it's making sure that each piece is positioned according to detailed design specifications. This precision prevents accidents and structural failures, fostering an environment where safety is paramount.

A pivotal factor in maintaining stability, particularly during column construction, is providing lateral support with appropriate bracing and connections. We've seen how essential this is in withstanding wind loading and mitigating risks associated with it. We can't afford to overlook this element – it's a cornerstone of our safety measures.

We also need to exercise patience when it comes to removing wall and column forms. They shouldn't be removed prematurely, we need to give the concrete time to set properly and support its own weight. This approach doesn't just ensure safety; it also guarantees the robustness and longevity of the structure we're building.

Beyond these measures, we're also advocating for the utilization of standard formwork frames. These frames aren't chosen at random; they're designed to withstand potential impact loads. This is an essential safety measure that we can't stress enough. It's not just about what's convenient or expedient – it's about what's safe, reliable, and sustainable.

These safety measures in formwork construction aren't optional. They're necessary, forward-thinking strategies that guarantee our work isn't just effective, but also safe. This is how we liberate ourselves from potential risks and build with confidence and security.

Formwork Removal Process

Dismantling the formwork from columns, a process known as formwork removal, requires a methodical approach to guarantee the integrity and quality of the finished structure. This process isn't just about tearing off the formwork; it's a calculated procedure that demands careful planning and execution.

To guarantee effective formwork removal, we've identified a sequence of actions that must be adhered to:

- Loosening the formwork clamps and supports to release the structure.

- Removing the formwork panels in a systematic manner to avoid any damage to the concrete.

- Inspecting the concrete surface for any defects or imperfections during the removal process.

- Taking caution not to damage the concrete surface while dismantling the formwork.

- Implementing proper handling techniques during the removal process to ensure the quality of the finished column structure.

This list provides a roadmap for an effective formwork removal process, making sure that each step is undertaken with the utmost care to preserve the quality of the concrete surface and the integrity of the final structure.

However, we must also be forward-thinking and consider the sustainability of our actions. It's not just about the present task at hand, but also about the impact our actions have on subsequent tasks and the environment. Ensuring careful and efficient formwork removal reduces waste, minimizes damage to the environment, and promotes the reuse and recycling of formwork material.

Comparing Different Formwork Types

Exploring the domain of formwork types, we encounter a diverse range of materials each with its unique strengths and limitations, from the cost-effective yet pest-prone timber to the robust and reusable steel.

Timber formwork, although cheap and flexible, isn't ideal for large, intricate projects due to its short lifespan and susceptibility to pests. It's like a double-edged sword- affordable but limited in durability.

On the other hand, aluminum formwork stands out as a versatile contender. Its strength, durability, and lightweight nature speed up construction while saving time and labor costs. It's an excellent choice for symmetrical structures, offering a balance between cost and efficiency.

Then, we've steel formwork. Fabricated from thin plates, it's impact-resistant and reusable, making it a cost-effective option for symmetrical structures. It also offers less concrete adhesion, which means faster construction times. It's like a stalwart soldier- always ready for action and unfazed by impacts.

Next is plastic formwork. Assembled with interlocking panels, it's suitable for foundations, small walls, and pillars. It's lightweight, crane-independent, and offers lower fresh concrete pressure. Consider it the underdog- small but capable, offering unique advantages in certain scenarios.

Lastly, plywood facing for formwork is less expensive than steel, lightweight, and reusable, although prone to moisture absorption and not as durable as steel. It's the middle ground- not too expensive, not too cheap, and with a decent lifespan.

In the end, the choice of formwork depends on project requirements, budget, and desired outcome. It's about finding the right fit, the perfect balance between cost, durability, and efficiency.

Frequently Asked Questions

What Type of Formwork Is a Column?

We're often asked, 'What type of formwork is a column?'

It's not a type of formwork, but rather, formwork is used in its creation. This involves setting up molds, typically made from steel or timber, to shape and support the column as the concrete cures.

Method and material choice depends on column design and project requirements.

It's an essential step, ensuring safety and structural integrity in construction.

Which Types of Formwork Are Used in Construction?

We're acquainted with different types of formwork utilized in construction. These encompass slab formwork for horizontal structures, wall formwork for vertical elements, and column formwork for pillars.

Each type serves a distinct purpose, such as providing support during concrete pouring and curing, and they're typically crafted from materials like steel, wood, or plastic.

It's essential to choose the right formwork to guarantee the safety and integrity of the construction project.

What Is the Formwork Method of Construction?

We're discussing the formwork method of construction. It's where we make a mold, often out of steel, timber, or plastic, to shape and hold concrete until it hardens.

We've got to be sure we've got the right design and installation for these forms, as they're essential for the structural integrity and safety of the columns. It's a precise process, but with careful selection and erection, we can achieve the desired strength and shape.

What Is the Method of Construction of Column?

We build a column by first setting up the formwork, which acts as a mold for the concrete.

We then pour the concrete into the formwork and allow it to cure. Once it's hardened, we remove the formwork.

It's important to check for plumbness and alignment during setup to guarantee the column's structural integrity.

Different methods, such as using column clamps and steel wedges, can enhance the efficiency of this process.

Conclusion

To sum up, we've explored various types and methods of formwork for column construction. We've delved into the intricacies of design, the diversity of materials, safety measures, and the removal process. Each formwork type offers unique advantages and potential challenges.

Looking ahead, we'll continue to see innovation in this space, with increasing focus on sustainability and efficiency. The careful selection of formwork is, and will remain, integral to successful column construction.