Formwork for Water Retaining Structures: Waterproofing Solutions

When constructing water retaining structures like dams or tanks, our main goal isn't just sturdy formwork, but solid waterproofing solutions. We rely on specific formwork systems, such as plated or flanged water barriers that bolster waterproofing effectiveness. To enhance this, we utilize high-quality sealants and membranes. Products like the Koster Deuxan 2c are essential for achieving complete water resistance. We aim to prevent concrete deterioration, maintain structural integrity, and guarantee longevity. An exploration deeper into our range of techniques will unfold more about how we accomplish these.

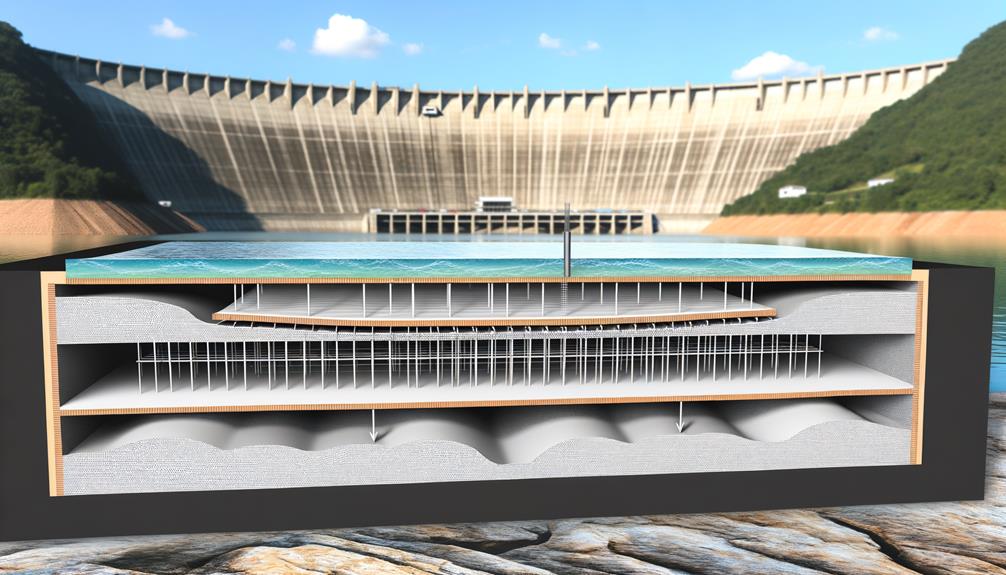

Understanding Water Retaining Structures

Exploring the realm of water retaining structures, it's crucial to comprehend that these structures, such as reservoirs, dams, or tanks, are intricately crafted to hold back water and necessitate specialized formwork to create walls that are impenetrable to water leakage. These structures are a testament to the innovation of engineering, and their successful implementation hinges on a keen understanding of both their physical structure and the materials used to construct them.

In the design phase, the focus is on developing a formwork system that isn't only structurally sound but also capable of withstanding the immense pressure exerted by the water it's meant to contain. This is where formwork systems like flanged or plated water barriers come into play. These systems provide the necessary strength and resilience to ensure that the structure stays intact even under extreme conditions.

However, the challenge doesn't end there. The chosen formwork must also be impermeable to water, a task easier said than done. This is where the effectiveness of the formwork design is truly tested. Various sealants and membranes are often used in the construction process to enhance the waterproofing capabilities of these structures.

Importance of Waterproofing Solutions

Building on the challenges of formwork design, we can't overlook the importance of waterproofing solutions in maintaining the integrity and functionality of water retaining structures. These solutions aren't just an exploration, but the crux of ensuring the longevity and efficiency of these structures. Let's dig deeper into why waterproofing holds such a significant place in formwork design.

Water ingress, if left unchecked, can cause severe damage to the structure. It increases the risk of concrete deterioration, leading to leaks and structural instability. Through proper waterproofing, we can prevent this water ingress, thereby maintaining the structural integrity of the concrete walls. It's not just a protective measure, it's a necessity.

We've got specialised waterproofing solutions like flanged and plated water barriers, designed specifically for use in water retaining structures. These solutions seal the construction joints effectively, preventing any water leakage. The choice of the right solution, however, is equally important. We can't just slap on any waterproofing product and hope for the best. It requires careful selection and application of reliable and durable products like Koster Deuxan 2c.

Exploring Different Waterproofing Techniques

While we've touched on the importance of waterproofing solutions, it's now essential to explore various techniques that can effectively seal structures from water ingress, particularly focusing on Insulating Concrete Formwork (ICF) walls. These techniques are key to achieving the liberation from water damage that our audience seeks.

Firstly, it's vital to mention that waterproofing ICF walls is particularly important for basements and retaining walls. These areas are often prone to water ingress due to their proximity to the ground. By guaranteeing that these walls are effectively waterproofed, we provide a strong barrier against water, thereby securing these structures.

One of the most recommended techniques is the use of fully bonded, liquid applied systems such as Koster Deuxan 2c. This system offers an exceptional level of waterproofing, ensuring that water can't penetrate the structure. It's important to have adequate access to the outside of the ICF wall when applying these systems, to guarantee extensive coverage.

In addition to using effective waterproofing systems, the preparation of the ICF wall is equally vital. This includes thoroughly cleaning the wall before applying the waterproofing system, and using free lime blockers like Koster Polysil TG500 to enhance the results. After these steps, Koster Deuxan 2c should be applied in two coats using a trowel or spray.

Preventing Risks With Waterproofing

In our quest to prevent potential risks associated with water damage, it's clear that a thorough waterproofing strategy isn't just beneficial – it's crucial. A robust waterproofing plan can effectively prevent water ingress, thereby nullifying the potential for consequential structural damage.

To guarantee the longevity and effectiveness of our water retaining structures, we must employ proper waterproofing techniques. These methods help maintain the integrity of the concrete walls, acting as a shield against leaks that could compromise the structure's stability over time. This is where the significance of using high-quality waterproofing products comes into play. Utilizing superior products reduces the risk of water seepage and mold growth – two common threats that can lead to serious damage if left unaddressed.

Waterproofing isn't just about maintaining the aesthetic appeal of these structures. More importantly, it underpins the structural integrity and safety of water retaining structures. Fundamentally, effective waterproofing is an investment in the future of our structures, ensuring they can withstand the test of time and continue to perform their function efficiently.

In the pursuit of liberation, we mustn't overlook the necessity to prevent risks, safeguarding our structures against the potential havoc that water can wreak. We're not just protecting our structures from damage – we're also preserving resources, saving costs, and upholding safety.

Enhancing Lifespan of Retaining Structures

To greatly improve the lifespan of our water retaining structures, it's important to utilize appropriate waterproofing solutions, efficiently preventing water ingress and reducing the risk of structural damage over time. The integration of specialized water barriers in formwork, for instance, aids in creating a watertight seal in concrete walls, greatly enhancing the longevity of these structures. This innovative approach to waterproofing is more than just a protective measure; it's a strategic investment in the durability of our water retaining structures.

One of the most efficient protective measures we've found is the use of plated water barriers with metal sleeves. These offer an exceptional level of protection, acting as a shield against water intrusion. Their robust and resilient nature allows for a high degree of water resistance, effectively safeguarding the integrity of the structural formwork.

However, our commitment to enhancing the lifespan of these structures goes beyond the initial construction phase. We also implement post-applied waterproofing systems that ensure long-term durability. This method allows us to continue protecting the structure even after the formwork is removed, providing an additional layer of defense against water ingress.

In the quest for liberation from the inevitable decay brought about by water ingress, these waterproofing strategies offer a path towards freedom. They guarantee that our water retaining structures, whether they be dams, reservoirs, or water tanks, stand the test of time. By doing so, they present a tangible solution to the challenge of maintaining these structures, making them resistant to the unforgiving forces of nature. Essentially, the right waterproofing solution can transform a vulnerable structure into a resilient, long-lasting asset.

Frequently Asked Questions

What Kind of Cement Is Used for Water Retaining Structures?

We've found that Portland cement is typically used for water retaining structures due to its durability and resistance to water. Type II cement is also a good choice, as it offers moderate sulfate resistance.

To enhance durability, we might use blended cements like Type IS or IP. For mass concrete placements, low heat cement is ideal to avoid thermal cracking.

How Do You Waterproof Exterior Concrete?

We're big fans of using a fully bonded, liquid applied system like Koster Deuxan 2c to waterproof exterior concrete. But remember, we've got to clean that surface thoroughly before we start applying anything.

We can't neglect those internal angles either – a product like Koster Repair Mortar Plus will do the trick. And let's not forget about backfill protection to prevent damage.

Always seek expert advice – we want these solutions to last, after all.

Can You Get Waterproof Concrete?

Yes, we can indeed get waterproof concrete. It's a specialized type of concrete that we create by adding hydrophobic admixtures during the mixing process.

This reduces water absorption which is essential for structures exposed to water. This type of concrete helps us prevent water leakage and seepage, thereby enhancing the durability of our structures.

We're not only protecting our infrastructures but also innovating for a more sustainable future.

What Are the Joints in a Water Retaining Structure?

We're often asked about the joints in a water retaining structure. These are important points where different parts intersect.

Three common types include construction, expansion, and control joints. It's essential we properly seal these joints to prevent water leakage.

This not only maintains the structure's integrity but also its longevity. So, effective sealing of joints isn't just desirable, it's absolutely necessary in order to avoid water damage.

Conclusion

To sum up, we've uncovered the critical significance of waterproofing in water retaining structures. Through examining different techniques, we've grasped how it helps reduce risks and prolong the lifespan of these structures.

This innovative perspective highlights that waterproofing isn't just an option, but a necessity. Therefore, ensuring proper waterproofing solutions is essential to the successful construction and maintenance of water retaining structures, ultimately enhancing their durability and functionality.