Formwork for Tunneling Projects: Key Design Factors

In tunneling projects, key design factors for formwork technology significantly shape the construction aspects. Material strength, stability, and project-specific customization are essential. Analyzing geotechnical data and optimization at each stage enhance the process. Safety, geological challenges, material selection, cost efficiency, and project timeline all impact formwork. You'll find high-quality outcomes with PERI's all-encompassing tunnel solutions with their mastery of any construction dance. So, the transformative effect of well-executed formwork on regional economies can't be overstated. Follow along, you're about to uncover the intricacies of how these factors all come together.

Understanding Formwork Technology

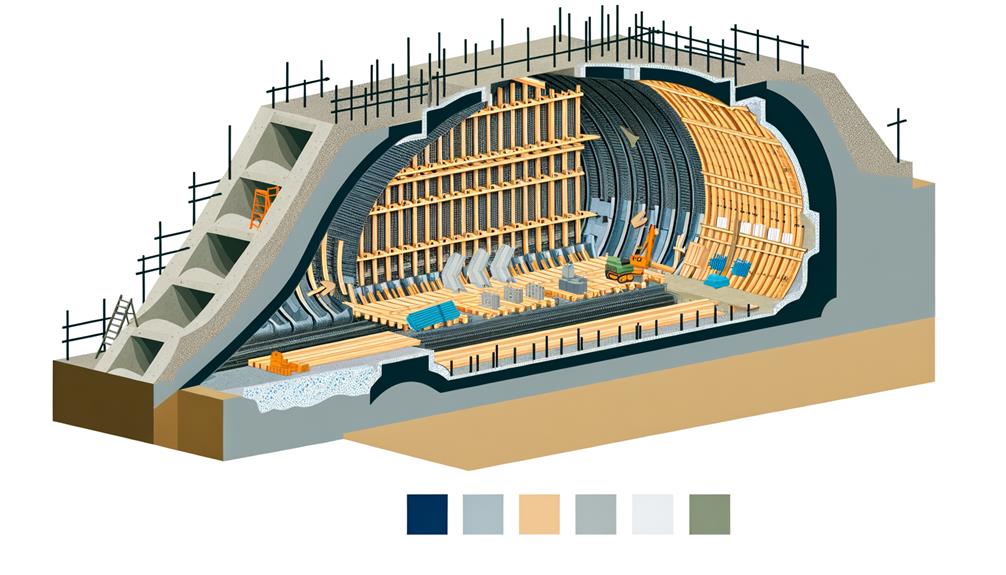

Delving into the heart of tunneling projects, it's crucial to grasp that formwork technology, the art of crafting temporary molds for concrete placement, fundamentally determines the shape, alignment, and finish of the tunnel construction. This technology, far from trivial, functions as an architectural blueprint, guiding the concrete into its final form with precision and accuracy.

We're talking about an intricate process here. The design factors of tunnel formwork, including material strength, stability, and evaluation of project requirements, come into play. These aren't just abstract concepts; they're critical considerations that directly impact the tunnel's integrity and quality. We can't afford to overlook any of these elements as they secure the structural soundness of our construction.

Let's not forget, formwork technology isn't a one-size-fits-all solution. It's about customizing the approach to fit the specific needs of each project. That means analyzing the geotechnical data, evaluating the project's demands, and developing a formwork design that perfectly aligns with these parameters.

The power of formwork technology lies in its ability to optimize each stage of the tunnel construction process. By understanding and effectively applying this technology, we're not just building a tunnel; we're sculpting a masterpiece. And the beauty of it? It's not just about aesthetics. It's about delivering an efficient, cost-effective solution that stands the test of time.

Basic Principles of Tunnel Construction

Expanding on our comprehension of formwork technology, let's now shift our focus to the fundamental principles governing tunnel construction. At the core of tunnel construction lies one central objective: creating efficient traffic routes by overcoming natural barriers and reducing distances. This practice is crucial in shaping global transport networks, driving international economic connections through seamless traffic flows.

Concrete technology forms the foundation of systematic tunnel construction. Depending upon the geological conditions, various load-bearing structures are employed. The selection of concrete formwork, thus, isn't simply a matter of technical preference. It's a strategic decision that directly impacts the project's longevity, safety, and overall economic feasibility.

Specializing in tunnel construction planning and execution, PERI stands as a beacon of expertise in the industry. They provide thorough solutions, covering all stages of a tunnel structure's life cycle. Their unique selling point lies in their innovative VARIOKIT engineering construction kit. This kit ensures a flexible and cost-effective system solution, tailored to meet the distinctive requirements of each project.

In essence, tunnel construction is a delicate balance of engineering prowess, economic considerations, and environmental sensitivity. It's an intricate dance, choreographed to the tunes of geology, technology, and economy. And as we move towards a world that craves liberation and connectivity, mastering this dance becomes increasingly significant.

In the next part of our discussion, we'll explore further into PERI's tunnel solutions. We'll take a closer look at how this leading company harnesses the power of formwork technology to build tunnels that aren't just functional and cost-effective, but also a tribute to engineering brilliance.

Examples of PERI Tunnel Solutions

Explore the innovative examples of PERI's tunnel solutions, highlighting the remarkable efficiency and precision of their VARIOKIT engineering construction kit in various global projects. This system has been pivotal in shaping tunnel solutions across the world, underlining its versatility and reliability. It's a proof to the design ingenuity that PERI is renowned for, and a key reason why they're chosen for critical infrastructure projects.

From the bustling cityscape of the UAE to the tranquil landscapes of Sweden and Denmark, PERI's tunnel construction technology has left an indelible mark. Their solutions have been implemented across diverse geographies, demonstrating a global reach and impact that's hard to match. In Ireland and Switzerland, PERI's expertise is etched into the heart of the infrastructure, playing an instrumental role in the countries' development.

What sets PERI's tunnel solutions apart is their modular-type concept. The use of standardized components, coupled with digital planning tools, greatly enhances efficiency and precision in construction. It's an approach that's less about reinventing the wheel and more about refining it, ensuring the best possible results in every project.

At the core of PERI's success is a diverse team of experts, including geologists, geodesists, and concrete technologists. Their collective knowledge and experience are invaluable assets, guaranteeing high-quality outcomes in tunnel projects. It's this fusion of technology, expertise, and innovative thinking that cements PERI's reputation as a specialist in tunnel construction. It's not just about building tunnels. It's about shaping the future.

Features of Tunnel Construction

As we explore the world of tunnel construction, it's worth noting that its worldwide boom since the 1960s is evidence of its vital role in expanding traffic networks, enhancing safety, and fostering international economic growth. Tunnels aren't just feats of engineering; they're a proof of human ingenuity and our unwavering commitment to overcoming natural barriers to connectivity.

Tunnels are paramount for efficient traffic flow, reducing distances by piercing through mountains and under water bodies. They symbolize technological prowess while also guaranteeing environmental preservation. Tunnels and bridges play a pivotal role in shaping efficient traffic routes, thereby enabling time and cost savings.

One of the key features of tunnel construction is its transformative effect on regional economies. By fostering efficient traffic flow, tunnels fuel the development of economic regions. Additionally, they're often strategically placed to connect economically vibrant areas, promoting trade and ensuring seamless transit.

However, constructing these architectural marvels is no easy feat. It requires careful planning, innovative designs, and meticulous execution. The use of formwork, for instance, is a critical aspect of tunnel construction. Formwork ensures the stability and strength of the tunnel structure, providing a mold where the concrete can set and harden.

Factors Influencing Tunnel Construction

While the marvel of tunnel construction encapsulates human ingenuity, it's crucial to acknowledge the various factors that greatly influence these complex projects. The dynamic environment of these initiatives demands a continual evolution of design modifications, while unforeseen conditions pose a constant challenge to project execution.

We can break down the factors influencing tunnel construction into five major categories:

- Concealment challenges: Tunnel projects often encounter unforeseen conditions that can derail progress. The subsurface environment is largely hidden, making it difficult to predict and plan accurately.

- Dynamic design modifications: The fluid nature of tunnel projects necessitates constant changes to the design. This requires a high level of adaptability and innovation.

- Geological risks: Conditions such as instability and interference pose significant risks to tunnel construction. These can be exacerbated in harsh environments, making effective risk management critical.

- Human factors: The safety of the project team is paramount. Detailed hazard analysis and targeted control measures must be implemented to mitigate risks.

- Material and equipment factors: The quality of materials and equipment used plays a crucial role in the overall quality of the construction. Ensuring the best resources are utilized is essential for the success of the project.

In essence, we're dealing with a confluence of variables that demand meticulous planning, constant vigilance, and a proactive approach. These factors don't just influence tunnel construction—they define it. Despite these challenges, we're driven by the prospect of liberation, the promise of progress, and the human spirit's indomitable will to conquer the seemingly insurmountable.

Control Measures in Tunnel Construction

Building on our understanding of the challenges associated with tunnel construction, let's now turn our focus towards the control measures deployed to guarantee the quality, safety, and efficiency of these projects. Supervision of excavation sites forms an essential part of this control, addressing quality issues such as over-excavation and under-excavation. This ensures that the project adheres to construction standards, enhancing overall construction quality.

A second pillar of control measures lies in anchor shotcrete support control. We implement acceptance methods and stringent quality checks to guarantee structural integrity. It's vital we prevent cracks and water seepage, thereby maintaining the stability and durability of tunnel structures.

In the face of potential safety hazards and settlement issues, effective control measures are more than a mere necessity; they are a lifeline. We cannot compromise on safety, and these measures are instrumental in maintaining project timelines and ensuring superior quality.

Below is a summary of the key control measures:

| Control Measure | Significance |

|---|---|

| Supervision of excavation sites | Prevents over and under-excavation, ensuring adherence to construction standards. |

| Anchor shotcrete support control | Guarantees structural integrity, prevents cracks and water seepage. |

| Safety and settlement control | Prevents safety hazards, maintains project timelines, ensures quality. |

Factors in Formwork Material Selection

In tunnel construction, our choice of formwork material can greatly steer the project's success, impacting everything from cost overruns to construction efficiency. The selection process involves a detailed analysis of several factors, each playing a significant role in the overall project outcome.

The type of formwork material utilized dictates the quality of the tunnel surface. The surface quality is a critical aspect, as it directly impacts the final structure's durability and aesthetics. As a result, our material choices must align with the specific requirements of the project to guarantee the highest quality standards.

Our formwork material selection also directly influences the construction cost and the cycle per floor. Each material—be it timber, steel, aluminum, or plastic—has distinct costs and potential efficiencies associated with its use. As such, a thorough cost-benefit analysis should inform our selection process.

However, our selection doesn't just affect the immediate construction process. It also dictates subsequent project activities, impacting the project timeline and overall efficiency. Hence, we need to take into account the long-term implications of our choices.

To avoid unnecessary delays and guarantee smooth tunnel construction processes, we must take into account the following factors:

- The specific requirements of the project

- The cost-efficiency of the material

- The impact on the construction timeline

- The quality of the surface produced

- The long-term implications of the material choice

Relevant Studies and References

Numerous studies and references explore the intricacies of formwork for tunneling projects, offering valuable insights into design efficiency, cost-effectiveness, and structural integrity. These scholarly resources provide a deeper understanding of material selection, construction methods, and formwork systems, which are all vital in the design and execution of tunneling projects.

In terms of material selection, the studies underscore the need for sturdy, durable, and adaptable materials. Not only do these materials need to withstand the pressure and wear-and-tear of the tunneling process, they also have to cater to the unique specifications of each project. The adaptability of formwork systems is another major focus. Research emphasizes the importance of system flexibility—being able to adjust to varying tunnel sizes, shapes, and ground conditions. This adaptability can lead to significant cost savings in the long run.

Comparative analyses also shed light on the speed and cost-effectiveness of tunnel formwork. In these analyses, tunnel formwork often emerges as a faster, more affordable option compared to traditional construction methods. It's not only about the initial cost, but also about the ongoing maintenance and durability of the structures.

Lastly, the references explore strength analysis, cost considerations, and seismic performance evaluation of tunnel formwork structures. These evaluations consider factors such as soil conditions, seismic loading, and safety provisions, giving us a detailed picture of what goes into creating effective, safe, and cost-efficient tunnel formwork. Ultimately, these studies and references free us from old, inefficient methods, leading us towards innovative, smart, and sustainable tunneling practices.

Frequently Asked Questions

What Are the Factors Affecting the Design of Tunnels?

We're considering several key factors in tunnel design. Geological conditions have a significant impact on stability and construction methods. The tunnel's shape, size, and cross-section influence our formwork requirements.

We must also consider environmental factors such as the water table and ground conditions. Traffic requirements and safety standards are vital too.

What Are the Factors Controlling the Design of Formwork?

We've found that formwork design is influenced by a multitude of factors. These include the shape and size of the tunnel, the type of concrete mix used, and the loading conditions. Construction methods, structural strength requirements, and safety measures also play critical roles.

Additionally, the material's durability, adaptability to conditions, and ease of assembly are important. It's a complex process that demands innovative, detail-oriented planning.

What Are the Main Factor to Be Considered for Construction of a Tunnel?

We've found that the main factors we must consider when constructing a tunnel are:

- Geological conditions

- Safety measures

- Quality control during excavation

- Advancements in construction technology

- Strict adherence to construction standards

It's our responsibility to guarantee the highest level of safety and efficiency, leveraging technological innovations and maintaining rigorous supervision and control measures.

We're dedicated to delivering tunnels of the highest quality, free from issues like cracks or water seepage.

What Are the Factors Affecting Tunneling?

We're considering several factors impacting tunneling. Geological risks, such as instability and harsh conditions, are significant. We must also account for human factors in our safety hazard analysis. Material and equipment quality play a huge role too.

These dynamic environments often require design changes mid-project, so we're always ready to adapt. It's a complex process, but we're dedicated to addressing these challenges to guarantee successful tunnel construction.

Conclusion

In wrapping up, we've examined the complexities of tunnel construction and the pivotal role of formwork technology.

We've explored PERI solutions, considered influencing factors, control measures, and material selection. Understanding these elements allows us to innovate and optimize our projects, ensuring safety and efficiency.

Our analysis underscores the importance of continuous research and learning in this evolving field. Remember, every decision counts in shaping the future of tunnel construction.